Enhancing Your Business with Strategic Mould Manufacturing

The mould manufacturing company sector is a vital player in today’s global economy, providing the essential service of producing molds that are critical for the production of numerous plastic components. In this article, we will explore the intricacies of this industry, particularly focusing on the expertise of Hanking Mould, a premier provider of plastic injection molds.

The Importance of Mould Manufacturing

In various industries, particularly automotive, consumer goods, and electronics, moulds serve as the backbone of mass production. The significance of a reliable mould manufacturing company like Hanking Mould cannot be overstated. Let’s delve into the reasons why mould manufacturing is crucial:

- Precision and Efficiency: High-quality moulds ensure precision in every single part produced. This leads to enhanced efficiency in manufacturing processes.

- Cost-Effectiveness: A well-manufactured mould can produce thousands of parts, significantly driving down the cost per unit.

- Innovation: Advanced mould-making technologies enable innovative designs that were previously hard to achieve.

- Customization: Moulds can be designed to meet specific customer requirements, allowing businesses to produce unique products.

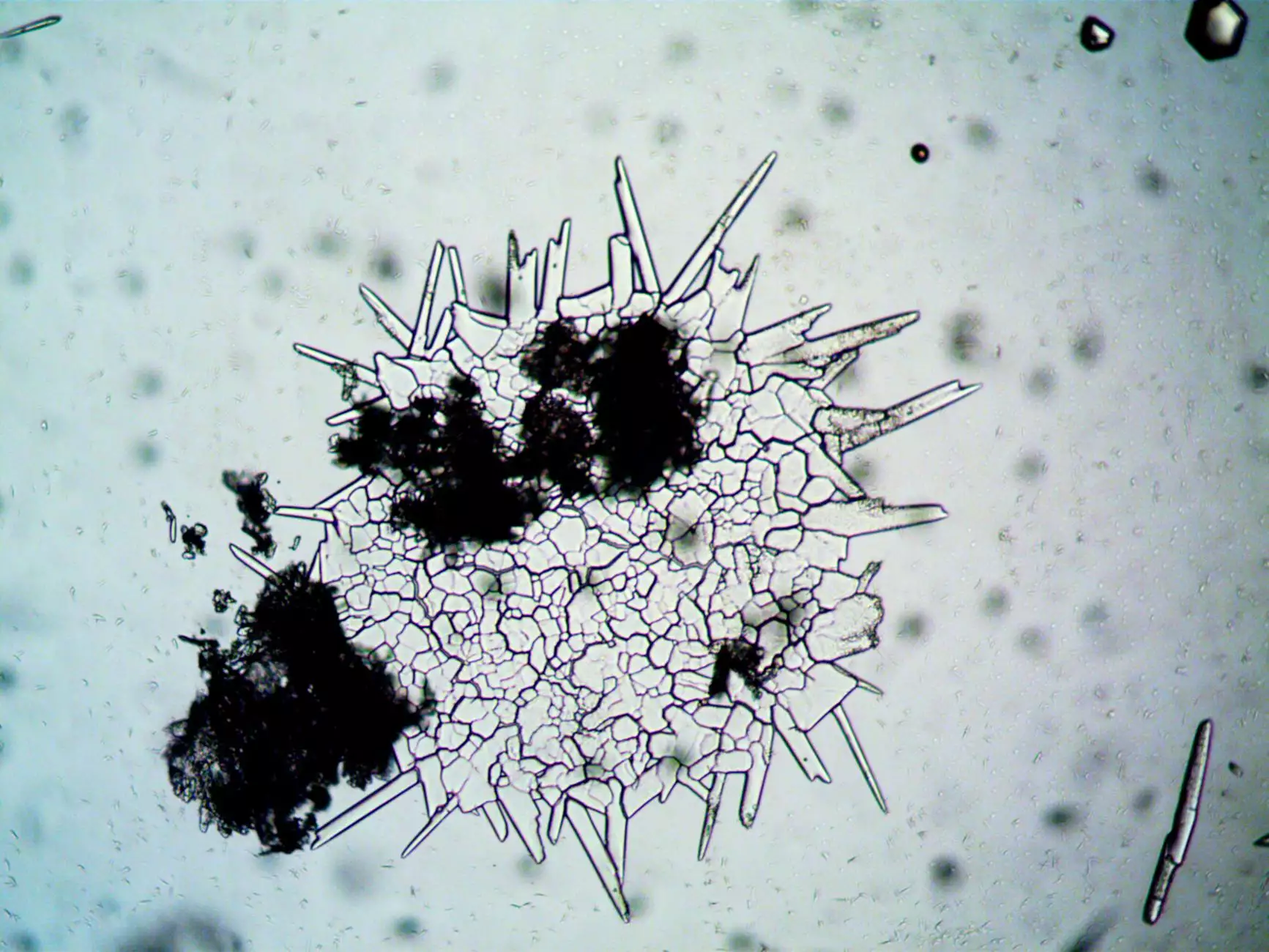

Understanding Plastic Injection Moulding

Plastic injection moulding is a highly efficient manufacturing process used to produce parts in large volumes. The process involves injecting molten plastic into a mould, allowing it to cool and solidify into the desired shape. Here are some key aspects of this process:

How Plastic Injection Moulding Works

- Material Selection: Different types of plastics are chosen based on their properties and the final product requirements.

- Melting the Plastic: The selected plastic pellets are heated until they melt into a viscous liquid.

- Injection: The molten plastic is injected into the mould at high pressure and speed.

- Cooling: The mould is cooled, allowing the plastic to solidify and take the shape of the mould.

- Mould Removal: Once cooled, the mould opens, and the finished part is ejected.

The Advantages of Plastic Injection Moulding

There are several advantages to using plastic injection moulding as a manufacturing process, which include:

- High Production Rates: Ideal for mass production with high efficiency.

- Complex Designs: Capable of creating intricate shapes and features.

- Durable Parts: Produces strong, durable components that stand the test of time.

- Material Versatility: Can use a wide variety of plastic materials and composites.

Hanking Mould: Leaders in Mould Manufacturing

Hanking Mould stands at the forefront of the mould manufacturing industry. With years of experience in producing plastic injection moulds, the company has developed a reputation for excellence. Here’s what sets Hanking Mould apart:

Expertise in Plastic Mold Making

As a premier plastic mold maker, Hanking Mould employs skilled engineers and technicians who are adept at designing and manufacturing precision molds. Their expertise ensures that all molds meet the strict quality and performance standards essential for effective plastic manufacturing. Some of their specializations include:

- Automotive moulds for parts like gear levers, dashboards, and interior components

- Consumer product molds for items such as packaging, toys, and household goods

- Electronics moulds for intricate components used in devices

Customer-Centric Approach

Hanking Mould prioritizes customer satisfaction by providing customized solutions that align with individual business needs. They engage closely with clients from the initial design phase to the final product delivery. This collaborative approach ensures:

- Tailored designs that meet specific requirements

- Timely project execution

- Ongoing support and guidance throughout the process

Innovation in Mould Technology

Innovation is key in the manufacturing industry, and Hanking Mould embraces advanced technologies to enhance its mould-making capabilities. Some of the latest innovations include:

Computer-Aided Design (CAD)

Utilizing CAD software allows for precise design and modifications before production commences. This reduces errors and enhances accuracy in the final output.

3D Printing for Prototyping

3D printing technology is used to create prototypes quickly. This allows manufacturers to visualize and test their parts before committing to full production.

Smart Moulding Technologies

Integration of smart technologies into moulds enhances monitoring, providing real-time data on the production process, optimizing operations, and improving quality control.

Quality Assurance in Mould Manufacturing

The hallmark of any reputable mould manufacturing company is its commitment to quality. Hanking Mould implements stringent quality assurance processes that include:

- Material Verification: Ensures only high-quality materials are used in the manufacturing process.

- Process Monitoring: Continuous monitoring of production processes to identify and rectify any issues.

- Final Inspection: All completed molds undergo a rigorous inspection to guarantee they meet design specifications and quality standards.

Environmental Considerations in Mould Making

As the world moves towards more sustainable practices, Hanking Mould is committed to minimizing its environmental impact. The company adopts eco-friendly manufacturing techniques such as:

- Using recyclable materials for mold production

- Implementing energy-efficient processes

- Adopting waste-reduction strategies during manufacturing

Future Trends in the Mould Manufacturing Industry

The future of the mould manufacturing industry looks promising, with several emerging trends that are likely to shape its trajectory:

Increased Use of Automation

Automation technologies such as robotics will continue to transform mould manufacturing, enhancing production rates and reducing costs.

Advanced Materials

There will be a growing focus on developing and using advanced materials that offer better durability and lower environmental impact.

Digital Twin Technology

This technology will enable manufacturers to create digital replicas of their molds to simulate and analyze performance, leading to further optimization.

Conclusion

Partnering with a reputable mould manufacturing company like Hanking Mould is essential for businesses looking to excel in the competitive landscape of plastics manufacturing. Their commitment to quality, innovation, and customer satisfaction positions them as a leader in the industry. Embracing the benefits of advanced mould making technology not only enhances production efficiency but also contributes to sustainable practices. As we look to the future of the mould manufacturing industry, staying ahead of the curve will be integral for businesses that aspire to thrive.

For more information on how Hanking Mould can elevate your production capabilities, visit hanking-mould.com today!